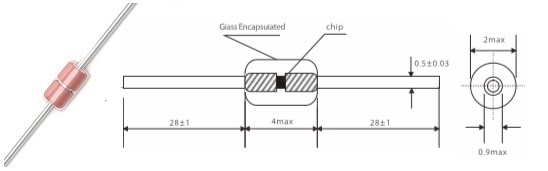

Axial Leaded Glass Encapsulated NTC Thermistors Temperature Sensor

Axial Glass NTC Thermistor

Axial Glass NTC Thermistor Temperature Sensor is transition metal oxide material made semiconductor NTC Thermistor chip hermetically sealed in DO35 glass shell, with axial tinned Dumet wire, for temperature sensing measurement detection, indicator, monitoring, gauging, control, calibration and compensation upto 250C centigrade.

- Glass body DO35 package provides hermetic seal & voltage insulation, can operate in high temperature and moisture environment.

- Small dimension, solid, convenient for automatic installation.

- Fast heat induction, high sensitivity.

- Operating temperature -45C to +250C.

- Nominal resistance @25C can be from 2kΩ— 1.388 million ohm.

- Typical resistance at 25C 2k ohm, 5k ohm, 10k ohm, 20k ohm, 47k ohm, 50k ohm, 100k ohm, 200k ohm, 500k ohm, 1.388 million ohm etc.

- Tight tolerance on resistance and beta value.

- Dissipation factor: ≥2.0 mW/C in still air.

- Thermal time constant: ≤12 seconds in still air.

In household electronics temperature measurement, detection and control: such as air-conditioners, micro-wave ovens, electric fans, and electric heaters, electric cookers, induction cooker, hair driers, etc.

Temperature detection and compensation of automatic office equipment, such as copiers and printers.

In heating and air conditioning (HVAC): in heating cost distributors, for room temperature monitoring, in under-flooring heating and gas boilers, for determining exhaust gas or burner temperature, outdoor temperature sensor.

Industrial electronics: for temperature stabilization of laser diodes and photo-elements, for temperature compensation in copper coils or reference point compensation of thermo-elements, etc. Also for temperature measurement and compensation of meters, instruments, integrated circuits, quartz crystal oscillators and thermocouples.

In telecommunication: for temperature measurement, compensation and control and protection of mobile phones, battery pack and battery charger, etc.

Glass encapsulated package NTC thermistor can also be used in temperature measurement, monitoring, detection and control of medical equipment, food processing equipment, climate, etc.

Unit: mm

| AMWEI Part Number | Resistance @25C R25 (K ohm) |

Beta value (K) |

Specific Temperature Point Resistance Data (ohm) |

|---|---|---|---|

| AMF58-202□3839(B5/25) | R25:2K ohm | B(5/25C):3839K | R5: 5.06K ohm |

| AMF58-502□3470 | R25:5K ohm | B(25/50C):3470K | |

| AMF58-502□3950 | R25:5K ohm | B(25/50C):3950K | |

| AMF58-103□3380 | R25:10K ohm | B(25/50C):3380K | |

| AMF58-103□3435(B25/85) | R25:10K ohm | B(25/85C):3435K | |

| AMF58-103□3470 | R25:10K ohm | B(25/50C):3470K | |

| AMF58-103□3600 | R25:10K ohm | B(25/50C):3600K | |

| AMF58-103□3700 | R25:10K ohm | B(25/50C):3700K | |

| AMF58-103□3950 | R25:10K ohm | B(25/50C):3950K | |

| AMF58-103□3975(B25/85) | R25:10K ohm | B(25/85C):3975K | |

| AMF58-103□4100 | R25:10K ohm | B(25/50C):4100K | |

| AMF58-203□3950 | R25:20K ohm | B(25/50C):3950K | |

| AMF58-233□4200 | R25:23K ohm | B(25/50C):4200K | |

| AMF58-303□3950 | R25:30K ohm | B(25/50C):3950K | |

| AMF58-40.27K□3979(B25/85) | R25:40.27K ohm | B(25/85C):3979K | |

| AMF58-473□3950 | R25:47k ohm | B(25/50C):3950K | |

| AMF58-503□3950 | R25:50K ohm | B(25/50C):3950K | |

| AMF58-503□4050 | R25:50K ohm | B(25/50C):4050K | |

| AMF58-98.75K□4300(B100/200) | R25:98.75KΩ | B(100/200C):4300K | R200: 0.55K ohm |

| AMF58-104□3899 | R25:100K ohm | B(25/50C):3899K | |

| AMF58-104□3930 | R25:100K ohm | B(25/50C):3930K | |

| AMF58-104□3950 | R25:100K ohm | B(25/50C):3950K | |

| AMF58-104□3990 | R25:100K ohm | B(25/50C):3990K | |

| AMF58-104□4200 | R25:100K ohm | B(25/50C):4200K | |

| AMF58-204□3899 | R25:200K ohm | B(25/50C):3899K | R160:3.0K ohm |

| AMF58-204□4200 | R25:200K ohm | B(25/50C):4200K | |

| AMF58-204□4260 | R25:200K ohm | B(25/50C):4260K | |

| AMF58-504□4050 | R25:500K ohm | B(25/50C):4050K | |

| AMF58-504□4260 | R25:500K ohm | B(25/50C):4260K | |

| AMF58-1.388M□4500 | R25:1388K ohm | B(25/50C):4500K | R200:4.0K ohm |

Notes:□ in the part number for filling in resistance tolerance, optional for ±1%(F), ±2%(G), ±3%(H), or ±5%(J).

| Test | Standard | Test Conditions | ΔR25/R25 (typical) | Remarks |

|---|---|---|---|---|

| Low temperature storage | IEC 60068-2-1 | Storage at low category temperature: -30 oC, Time: 1000 hours |

≤3% | No visible damage |

| Storage in dry heat | IEC 60068-2-2 | Storage at upper category temperature: 200 oC, Time: 1000 hours |

≤3% | No visible damage |

| Storage in damp heat, steady state (Humidity test) | IEC 60068-2-3 | Temperature: 40oC, Humidity:90%-95% RH, Duration:1000 hours |

≤3% | No visible damage |

| Temperature cycling | IEC 60068-2-14 | 1. -30C/30 minutes 2. 80C/5 minutes 3. 200C/30 minutes 4. 80C/5 minutes. Number of cycles: 5 Cycles |

≤3% | No visible damage |

| Test | Standard | Test Conditions and methods | Requirements |

|---|---|---|---|

| Soldering & Solderability | IEC60068-2-20 Test Ta |

Temperature: 230±5 ℃, 2-2.5mm away from ceramic body On: 2±0.5 Seconds. |

The terminations shall be evenly tinned |

| Resistant to soldering heat | IEC60068-2-20 Test Tb |

Temperature: 260±5℃, 2-2.5mm away from ceramic body On:10±1 Seconds. |

No visible damage, ΔR25/R25 ≤3% |

| Lead wire tensile | IEC60068-2-21 Test U |

Test Ua: Force 10N, On 10 Seconds; Test Ub: Bending 90C, Force 5N, Twice. |

No break off, ΔR25/R25 ≤3% |

Minimum lead wire length tailored to shall be ≥8mm.

In lead wire bending, bending point shall be more than 2mm away from glass body part.

Mounting and Handling Recommendations

Excessive forces applied to a sensor may cause serious damage. To avoid this, the following recommendations should be adhered to:

- No perpendicular forces must be applied to the body

- During bending, the leads must be supported

- Bending close to the body must be done very carefully

- Axial forces to the body can influence the accuracy of the sensor and should be avoided

- These sensors can be mounted on a minimum pitch of >5 mm

Soldering and Welding

- Avoid any force on the body or leads during, or just after, soldering.

- Do not correct the position of an already soldered sensor by pushing, pulling or twisting the body.

- Prevent fast cooling after soldering.

- For hand soldering, where mounting is not on a printed-circuit board, the soldering temperature should be <300C the soldering time <3 s and the distance between body and soldering point >1.5 mm.

- For hand soldering, dip, wave or other bath soldering, mounted on a printed-circuit board, the

- soldering temperature should be <300C, the soldering time <5 s and the distance between body and soldering point >1.5 mm.

- The distance between the body and the welding point should be >0.5 mm. Care should be taken to ensure that welding current never passes through the sensor.

Other Related AMWEI NTC Thermistors Products for Temperature Sensing

Content Headline

Technical Knowledge

NTC Thermistor Glossary and Definition

How NTC thermistor beta value is calculated?

NTC Thermistor Manufacturing Process and Quality Control

Applications Articles

How to Select NTC Thermistor for Inrush Current Limiting?

NTC thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC thermistor

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select Packaged Thermistor Temperature Sensor Probe Assembly ? 6 Steps