Thermistors for Transformer Power Supply Application

Thermistors for Transformer Power Supply Application

Thermistors for Transformer Power Supply Application

Thermistors for Transformer Power Supply ApplicationPTC Thermistors Circuit Protector, also called PTC Thermistor Resettable fuse, are used instead of conventional fuses to protect motors against overcurrent for circuit protection. PTC thermistor over-current protector limits the power dissipation of the whole circuit by increasing their resistance and thus reducing the current to a harmless residual value. In contrast to conventional fuses, PTC thermistor resettable fuses do not have to be replaced after elimination of the fault but resume their protective function immediately after a short cooling-down time.

With PTC Thermistors as temperature sensors only the steep region of the R/T characteristic is used. The resistance of the PTC thermistor is to be regarded as a function of the ambient temperature [RPTC = f (TA)]. The precondition for this relationship between resistance and ambient temperature is that selfheating and/or the varistor effect are excluded. This means that these PTC thermistors must be operated in the lowest possible field strengths. To enable a fast response, thermistor sensors have especially small dimensions. High control accuracy is achieved by using materials with an extra steep resistance/temperature characteristic.

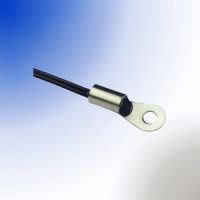

Battery Pack Temperature Sensor is a ring terminal temperature sensor that measures surface temperature. It is important to monitor the temperature on hybrid batteries for overcharging protection, as well as to optimize battery performance.

Ring lug NTC thermistor surface temperature probes are designed for screw-in-place mounting , can be used for temperature measurement, control, and monitoring of transformer and power supply, NTC thermistor housed in eyelet nickel plated copper material, Good thermal coupling through metal tag. Metal contact surface yields fast temperature response.

Standard ring hole diameter 4.0mm, 3.2mm, resistance @25C 10k ohm, 100k ohm.

NTC thermistor is part of a battery smart charging control unit, which assures that the ambient temperature is in the range allowing quick charging. During charging the NTC thermistor repeatedly measures the temperature all 5 to 10 seconds and can detect a rise in the battery cell’s temperature at the end of the charging cycle or precipitated from abnormal charging conditions. During discharging NTC thermistors also perform temperature compensation for the voltage measurement, which helps to measure the remaining charge in the battery.

The problem of current surges in switch-mode power supplies is caused by the large filter capacitors used to smooth the ripple in the rectified 60 Hz current prior to being chopped at a high frequency.

The NTC thermistor is ideally suited for this application. It limits surge current by functioning as a power resistor which drops from a high cold resistance to a low hot resistance when heated by the current flowing through it.

The main purpose of limiting inrush current is to prevent components in series with the input to the DC/DC convertor from being damaged. Typically, inrush protection prevents nuisance blowing of fuses or breakers as well as welding of switch contacts.

Thermistors Application

Technical Information

AMWEI PTC Thermistors Manufacturing Process and Quality Control

PTC Thermistors Glossary Definition.

PTC Thermistors Protect Converters MOSFET from Overheating

PTC Thermistor Limit Temperature Sensor for thermal monitoring makes hot spots under control

PTC Thermistor Meter Test Measuring instrument Protect.

What difference between Positive and Negative Temperature Thermistors?

PTC Thermistors Application Cautions for Soldering Mounting Cleaning.

How to Select PTC Thermistor for Overcurrent Overload Protection?

NTC Thermistor Glossary Definition.

AMWEI NTC Thermistor Manufacturing Process and Quality Control.

How NTC Thermistor beta value is calculated?

How to Select NTC Thermistor for Inrush Current Limiting?

NTC Thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC Thermistor

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select NTC Thermistor for Inrush Current Limiting?