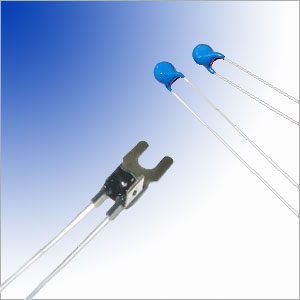

Silicon PTC Thermistor Temperature Sensor, Axial Leaded Glass Sealed DO35 Package, Resistance @25C 980-1000Ω, Operating Temperature -55C–+175C, Cross to NXP KTY83-121 Silistor.

Unit: mm

- Silicon chip hermetically sealed in DO35 glass shell.

- Tinned Dumet wire

Silicon Temp Sensor 1K RT Resistance vs. Temperature Characteristics Temperature (Centigrade C)

- High accuracy and reliability

- Long-term stability

- Positive temperature coefficient;

fail-safe behavior - Virtually linear characteristics

- Motion control temperature sensor, temperature sensing and controls in drives and motors, spindles, inverters and control systems, etc.

- Industrial automation control equipment.

- Precision circuit and crystal oscillator temperature compensation.

- Temperature compensation of silicon semiconducting devices.

- Temperature compensation of instrumentation amplifier.

- A/D converter temperature compensation.

- Micro motor timing control.

- Automobile temperature detection and control.

- Medical equipment temperature detection and control.

- Linear PTC thermistors applications also include transmission, engine oil and coolant, heating system, overheating protection, amplifiers, power supplies, transducers, telemetry, computers, magnetic amplifiers, thermometry, meteorology, temperature regulation and over-temperature protection.

Resistance at 25C: 980–1000Ω

Dissipation Factor:1.5mW/C min. in still air

Thermal Time Constant: 21 seconds max. in still air

Insulation Resistance: 100MΩ (DC=100V)

Maximum operating current: 8mA max.

Rated operating current 2mA

Rated Power: 50mW max.

Temperature measurement range: -55C~+175C

Storage time 2 Years (Room temperature, relative humidity <60%)

Isen(cont) = 1 mA.

| Ambient Temperature | Temperature coefficient (%/K) |

Resistance (Ohm) |

|

|---|---|---|---|

| (°C) | (°F) | ||

| -55 | -67 | 0.98 | 482 |

| -50 | -58 | 0.94 | 507 |

| -40 | -40 | 0.92 | 557 |

| -30 | -22 | 0.94 | 611 |

| -20 | -4 | 0.91 | 671 |

| -10 | 14 | 0.89 | 735 |

| 0 | 32 | 0.86 | 803 |

| 10 | 50 | 0.82 | 875 |

| 20 | 68 | 0.80 | 941 |

| 25 | 77 | 0.78 | 990 |

| 30 | 86 | 0.78 | 1030 |

| 40 | 104 | 0.75 | 1114 |

| 50 | 122 | 0.73 | 1200 |

| 60 | 140 | 0.71 | 1291 |

| 70 | 158 | 0.69 | 1386 |

| 80 | 176 | 0.68 | 1485 |

| 90 | 194 | 0.65 | 1589 |

| 100 | 212 | 0.62 | 1695 |

| 110 | 230 | 0.60 | 1803 |

| 120 | 248 | 0.57 | 1914 |

| 130 | 266 | 0.57 | 2026 |

| 140 | 284 | 0.55 | 2146 |

| 150 | 302 | 0.54 | 2260 |

| 160 | 320 | 0.52 | 2360 |

| 170 | 338 | 0.51 | 2424 |

| 175 | 347 | 0.51 | 2486 |

Minimum lead wire length tailored to shall be ≥8mm.

In lead wire bending, bending point shall be more than 2mm away from glass body part.

Mounting and Handling Recommendations

Excessive forces applied to a sensor may cause serious damage. To avoid this, the following recommendations should be adhered to:

- No perpendicular forces must be applied to the body

- During bending, the leads must be supported

- Bending close to the body must be done very carefully

- Axial forces to the body can influence the accuracy of the sensor and should be avoided

- These sensors can be mounted on a minimum pitch of >5 mm

Soldering and Welding

- Avoid any force on the body or leads during, or just after, soldering.

- Do not correct the position of an already soldered sensor by pushing, pulling or twisting the body.

- Prevent fast cooling after soldering.

- For hand soldering, where mounting is not on a printed-circuit board, the soldering temperature should be <300C the soldering time <3 s and the distance between body and soldering point >1.5 mm.

- For hand soldering, dip, wave or other bath soldering, mounted on a printed-circuit board, the

- soldering temperature should be <300C, the soldering time <5 s and the distance between body and soldering point >1.5 mm.

- The distance between the body and the welding point should be >0.5 mm. Care should be taken to ensure that welding current never passes through the sensor.