TDK EPCOS B59772C0120A070 Alternative, PTC 420V 150 Ohm 1.4A Overcurrent Protection Inrush Current Limiting

AMWEI Ordering Code: AMZ11A-08P151N420

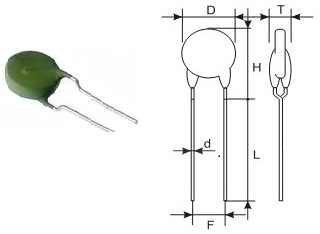

Appearance and Dimension

Leaded Disk Coated PTC Thermistor Appearance Engineering Drawing

- Silicon resin coated ceramic disk, green color

- Coated ceramic disk outer diameter D : 9mm max.

- Coated ceramic disk thickness T: 7.0mm max.

- 2 Tinned lead wire space F: 5.0± 1mm

- Pin wire diameter d: 0.6mm

- Pin wire length L: 25mm min.

- Ceramic body to kinked wire length H: 15mm max.

Features

- Application: Overcurrent protection, overload, short circuit protection, inrush current limiting.

- Best suited to meet the requirements for measuring instrumentation and meter circuit overload and short circuit protection.

- Error-free operations are assured by rush current.

- Circuit is protected until current is turned off.

- Restores the original low resistance value automatically once the overload is removed.

- Non-contact design leads to long life and no noise.

- Durable and strong against mechanical vibration and shock.

Electrical Specifications

- Resistance @25C R25 :150Ω +/- 30%

- Rated voltage (RMS) : 380 V

- Maximum operating voltage Vmax: 420 V

- Maximum withstanding voltage: 500V

- Maximum permissible repetitive turn over current Imax: 1.4A

- Hold Current (Non-trip Current) at +25℃ : 43 mA

- Hold Current (Non-trip Current) at +60℃: 35 mA

- PTC Thermistor Trip Current, Operating Current at +25℃ It : 86 mA

- Curie temperature (Switch temperature) : 120℃

- Operating ambient temperature range (V=0): -40~+125C

- Operating ambient temperature range (V=Vmax) : 0~60C

Reliability Data

| Test Item | Standard | Test conditions | |ΔR25/R25| |

|---|---|---|---|

| Electrical endurance, cycling |

IEC 60738-1 | Room temperature, 1.4A; 420V Number of cycles: 100 |

<25% |

| Electrical endurance, constant |

IEC 60738-1 | storage at Voltage: 230V Ambient temperature: +60C Test duration: 1000 h |

<25% |

| Damp heat | IEC 60738-1 | Temperature of air: 40℃, Relative humidity of air: 93%, Duration: 56 days Test according to IEC 60068-2-78 |

<10% |

| Lead wire tensile | IEC60068-2-21 | Test Ua: pull strength 10N, 10 seconds, Test Ub: bending 90°, pull strength 5N, successively twice. Test Uc: revolving 180°, successively twice. |

<20% |

| Rapid change of temperature |

IEC 60738-1 | T1 = Top,min (0 V), T2 = Top,max (0 V) Number of cycles: 5 Test duration: 30 min Test according to IEC 60068-2-14, test Na |

<10% |

| Climatic sequence | IEC 60738-1 | Dry heat: T = Top,max (0 V) Test duration: 16 h Damp heat first cycle Cold: T = Top,min (0 V) Test duration: 2 h Damp heat 5 cycles Tests performed according to IEC 60068-2-30 |

<10% |

Packaging Information

Loose bulk, or Production tape package.

What is PTC Thermistor Current Protector Resettable Fuse

PTC Fuse Current Protection Application

How PTC Thermistor Current Protection Work? Operating Principle

PTC Thermistor Replacement Idea for a Resistor and Fuse solution

PTC 3 types over-current and overload protection

PTC thermistor circuit protection diagram examples

Transformer Protection 265V, 100C Data

(For PTC fuse installed inside transformer windings coil)

Transformer Protection 265V 120C Data

(For PTC fuse installed outside transformer windings coil)

PTC thermistor Current Protector Reliability Data

How to select PTC thermistor circuit protector for overcurrent and overload protection?

An example selecting AMWEI PTC thermistor for transformer overload protection.