PTC Thermistor for Telecom Overload Proection,

Leaded Disk Coated 10 Ohm 250V 1A

Leaded Disk Coated 10 Ohm 250V 1A

AMWEI Ordering Code: AMZ23-10RM130

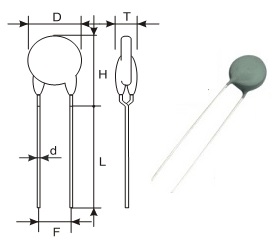

Appearance and Dimension

PTC Thermistor Radial Kinked Lead Resin Coated Drawing

- Silicon resin coated ceramic body, grey color

- Coated ceramic body outer diameter D : 7.5mm max.

- Coated ceramic body thickness T: 5.0mm max.

- Pin wire diameter d: 0.6mm

- 2 Tinned pin wire space F: 6.0± 1mm

- Pin wire length L: 25mm min.

- Coated ceramic body to wire length H: 14mm max.

Application

Overcurrent protection for telecom applications

Suitable for line card applications e.g. POTS, access networks,

customer premises equipment (CPE) or integrated voice data (IVD)

Features

Compliant with ITU-T standards

- basic-level lightning surges (10/700 µs)

- basic level power induction (600 V, 1 A, 0.2 s)

- power contact criteria A/B (230 V, 15 min.)

Matching available with narrow resistance tolerance.

Tight resistance matching maintained after switching.

Negligible resistance drift after soldering or switching.

Electrical Specifications

- Resistance @25C R25 : 10Ω,

- Standard R25 tolerance +/- 20%.

- Rated voltage (RMS) : 220 V

- Maximum operating voltage Vmax: 250 V

- Maximum withstanding voltage: 350V

- Maximum permissible repetitive turn over current Imax: 1 A

- Non-trip Current at +25C : 130 mA

- Non-trip Current at +40C: 110 mA

- PTC Thermistor Trip Current, Operating Current at +25℃ It :300 mA

- Tripping time at +25C: 1A→ 0.5A: < 2 seconds.

- Reference Temperature (Curie temperature, Switch temperature) : 110C

- Operating ambient temperature range (V=0): -40~+125C

- Operating ambient temperature range (V=230V) : 0~60C

Reliability Data

| Test Item | Standard | Test conditions | |ΔR25/R25| |

|---|---|---|---|

| Electrical endurance, cycling |

IEC 60738-1 | Room temperature, 1A; 230V Number of cycles: 100 |

<25% |

| Electrical endurance, constant |

IEC 60738-1 | storage at Voltage: 230V Ambient temperature: +60C Test duration: 1000 h |

<25% |

| Damp heat | IEC 60738-1 | Temperature of air: 40℃, Relative humidity of air: 93%, Duration: 56 days Test according to IEC 60068-2-78 |

<10% |

| Lead wire tensile | IEC60068-2-21 | Test Ua: pull strength 10N, 10 seconds, Test Ub: bending 90°, pull strength 5N, successively twice. Test Uc: revolving 180°, successively twice. |

<20% |

| Rapid change of temperature |

IEC 60738-1 | T1 = Top,min (0 V), T2 = Top,max (0 V) Number of cycles: 5 Test duration: 30 min Test according to IEC 60068-2-14, test Na |

<10% |

| Climatic sequence | IEC 60738-1 | Dry heat: T = Top,max (0 V) Test duration: 16 h Damp heat first cycle Cold: T = Top,min (0 V) Test duration: 2 h Damp heat 5 cycles Tests performed according to IEC 60068-2-30 |

<10% |

ITU Performance

| Test Item | Condition | Test Method | Performance Requirement |

|---|---|---|---|

| Over Current Withstanding | 220V/1A, 20 cycles |

Max. voltage of supply: 220VAC, Initial current: 1A. ON 60S, OFF 600S , Cycle:20 times, |

No damage, 4 hours after the conditioning then re-test Rn. Zero power resistance at 25℃ ΔR/Rn≤20%. |

| Lightning Surge Current Withstanding | 10/1000μs, 30 cycles |

Duration: 30 times, Temperature: 25℃ Short circuit current wave:10/1000μs, Minimum open voltage: 1.5 KV Short circuit current peak value: 25A Interval time: 3min |

No damage, 4 hours after the conditioning then re-test Rn. Zero power resistance at 25℃ ΔR/Rn≤20%. |

| Power Line Contact (Over Voltage Withstanding) |

250V/1A, 15 minutes |

Duration: 1 cycle Ambient Temperature: 25 ± 2 ℃ Voltage: 250 Vrms Frequency: 50Hz Current: 1A, 15 minutes On |

No damage, 4 hours after the conditioning then re-test Rn. Zero power resistance at 25℃ ΔR/Rn≤20%. |

| Fail Model | 250V/10A, 15 minutes |

Voltage of power supply: 250VAC. Initial current: 10Arms. Energized time: 15min. |

High resistance or open circuit is allowable. Low resistance state or firing is not allowed |

Packaging Information

Production tape package or loose bulk in plastic package.