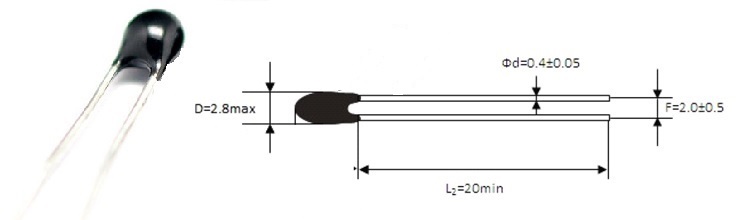

Radial Leaded Epoxy Resin Coated NTC Thermistor Temperature Sensor, 100K ohm, Beta B(25/50):3990K, Temperature -40C to +125C.

Unit: mm

Temperature sensing, control and compensation. E.g. inlet air temperature sensing thermistors or ECT in

automotive applications, sensor elements in industrial and commercial applications, heating systems and industrial

systems, medical equipment.

- Resistance at 25C R25: 100K ohm+/-2%

- Beta Value B(25/50): 3990K+/-1%

- Optional R25 resistance tolerance, ±1%(F), ±2%(G), ±3%(H), or ±5%(J)

- Dissipation Factor: δ≥3mW/℃.

- Thermal Time Constant (in still air): ≤12 seconds.

- Rated Powerwatt (below 25C): ≤50mW

- Insulation resistance: room temperature, 500V, 60 Seconds, ≥100MΩ.

- Operating temperature range: -40 to +125C.

| Temperature Centigrade |

Resistance (K Ohm) |

Temperature Centigrade |

Resistance (K Ohm) |

Temperature Centigrade |

Resistance (K Ohm) |

|---|---|---|---|---|---|

| -40C | 3360.378 KΩ | 20C | 125.023 KΩ | 80C | 12.396 KΩ |

| -35C | 2408.485 KΩ | 25C | 100.000 KΩ | 85C | 10.523 KΩ |

| -30C | 1749.400 KΩ | 30C | 80.437 KΩ | 90C | 8.960 KΩ |

| -25C | 1286.898 KΩ | 35C | 65.054 KΩ | 95C | 7.651 KΩ |

| -20C | 957.943 KΩ | 40C | 52.892 KΩ | 100C | 6.553 KΩ |

| -15C | 720.902 KΩ | 45C | 43.228 KΩ | 105C | 5.630 KΩ |

| -10C | 547.966 KΩ | 50C | 35.511 KΩ | 110C | 4.853 KΩ |

| -5C | 420.339 KΩ | 55C | 29.505 KΩ | 115C | 4.196 KΩ |

| 0C | 325.144 KΩ | 60C | 24.628 KΩ | 120C | 3.640 KΩ |

| 5C | 253.446 KΩ | 65C | 20.639 KΩ | 125C | 3.169 KΩ |

| 10C | 198.965 KΩ | 70C | 17.358 KΩ | ||

| 15C | 157.230 KΩ | 75C | 14.646 KΩ |

| Test | Standard | Test Conditions and methods | Requirements |

|---|---|---|---|

| Soldering & Solderability | IEC60068-2-20 Test Ta |

Temperature: 230±5 ℃, 2-2.5mm away from ceramic body On: 2±0.5 Seconds. |

The terminations shall be evenly tinned |

| Resistant to soldering heat | IEC60068-2-20 Test Tb |

Temperature: 260±5℃, 2-2.5mm away from ceramic body On:10±1 Seconds. |

No visible damage, ΔR25/R25≤3% |

| Lead wire tensile | IEC60068-2-21 Test U |

Test Ua: Force 10N, On 10 Seconds; Test Ub: Bending 90C, Force 5N, Twice. |

No break off, ΔR25/R25≤3% |

| Test | Standard | Test Conditions | ΔR25/R25 (typical) | Remarks |

|---|---|---|---|---|

| Low temperature storage | IEC 60068-2-1 | Storage at low category temperature. Temperature: -40 oC Time: 1000hours | ≤3% | No visible damage |

| Storage in dry heat | IEC 60068-2-2 | Storage at upper category temperature. Temperature: 100 oC Time: 1000hours | ≤3% | No visible damage |

| Storage in damp heat, steady state (Humidity test) | IEC 60068-2-3 | Temperature: 40oC, Humidity:90%-95% RH, Duration:1000 hours |

≤3% | No visible damage |

| Rapid temperature cycling | IEC 60068-2-14 | 1. -40C/30 minutes 2. 30C/5minutes 3. 100C/30 minutes 4. 30C/5minutes. Number of cycles: 5 Cycles |

≤3% | No visible damage |

Other Related AMWEI NTC thermistors Products for Temperature Sensing

Content Headline

Appearance & Dimension

NTC 100KΩ B3990 Application

NTC 100KΩ B3990 Electric Data

Resistance vs. Temperature RT Data

NTC 100KΩ B3990 Mechanical Test

NTC 100KΩ B3990 Reliability Data

Technical Knowledge

NTC Thermistor Glossary and Definition

How NTC thermistor beta value is calculated?

NTC Thermistor Manufacturing Process and Quality Control

Applications Articles

NTC thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC Thermistor

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select NTC Thermistor for Inrush Current Limiting?

How to Select Packaged Thermistor Temperature Sensor Probe Assembly ? 6 Steps