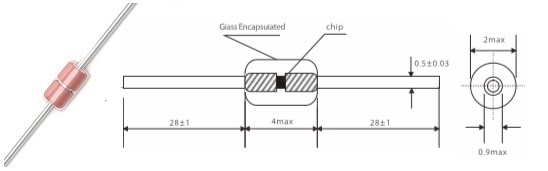

Axial Leaded Glass Encapsulated Diode DO35 Shape NTC Thermistor Temperature Sensor, 30K Ohm, Beta B(25/50): 3950K, Operating Temperature Range -40C to +250C.

Unit: mm

- NTC Thermistor chip hermetically sealed in DO35 glass shell.

- Tinned Dumet wire

Axial lead glass encapsulated NTC thermistor used for high temperature measurement, sensing, monitoring, detection and control. Typical application such as industrial process control, HVAC, oven, office equipment, etc.

- Resistance at 25C R25: 30K ohm+/-2%

- Beta Value B(25/50): 3950K+/-1%

- Optional R25 resistance tolerance, ±1%(F), ±2%(G), ±3%(H), or ±5%(J)

- Dissipation Factor: δ≥2mW/℃

- Thermal Time Constant (in still air): 12 seconds max.

- Rated Power: ≤50mW

- Insulation resistance: room temperature, 50VDC, 60 Seconds, ≥100MΩ.

- Operating temperature range: -40 to +250C.

| Temperature Centigrade |

Resistance (K Ohm) |

Temperature Centigrade |

Resistance (K Ohm ) |

Temperature Centigrade |

Resistance (K Ohm) |

|---|---|---|---|---|---|

| -40C | 959.724 KΩ | 80C | 3.735 KΩ | 200C | 0.183 KΩ |

| -35C | 691.335 KΩ | 85C | 3.178 KΩ | 205C | 0.166 KΩ |

| -30C | 504.740 KΩ | 90C | 2.714 KΩ | 210C | 0.151 KΩ |

| -25C | 373.230 KΩ | 95C | 2.326 KΩ | 215C | 0.138 KΩ |

| -20C | 279.278 KΩ | 100C | 1.999 KΩ | 220C | 0.126 KΩ |

| -15C | 211.269 KΩ | 105C | 1.724 KΩ | 225C | 0.115 KΩ |

| -10C | 161.417 KΩ | 110C | 1.492 KΩ | 230C | 0.106 KΩ |

| -5C | 124.437 KΩ | 115C | 1.295 KΩ | 235C | 0.097 KΩ |

| 0C | 96.700 KΩ | 120C | 1.128 KΩ | 240C | 0.089 KΩ |

| 5C | 75.704 KΩ | 125C | 0.986 KΩ | 245C | 0.082 KΩ |

| 10C | 59.559 KΩ | 130C | 0.864 KΩ | 250C | 0.076 KΩ |

| 15C | 47.112 KΩ | 135C | 0.760 KΩ | ||

| 20C | 37.483 KΩ | 140C | 0.671 KΩ | ||

| 25C | 30.000 KΩ | 145C | 0.593 KΩ | ||

| 30C | 24.156KΩ | 150C | 0.526 KΩ | ||

| 35C | 19.566 KΩ | 155C | 0.468 KΩ | ||

| 40C | 15.942 KΩ | 160C | 0.418 KΩ | ||

| 45C | 13.064 KΩ | 165C | 0.373 KΩ | ||

| 50C | 10.765 KΩ | 170C | 0.335 KΩ | ||

| 55C | 8.917 KΩ | 175C | 0.301 KΩ | ||

| 60C | 7.424 KΩ | 180C | 0.271 KΩ | ||

| 65C | 6.211 KΩ | 185C | 0.245 KΩ | ||

| 70C | 5.220 KΩ | 190C | 0.221 KΩ | ||

| 75C | 4.406 KΩ | 195C | 0.201 KΩ |

| Test | Standard | Test Conditions and methods | Requirements |

|---|---|---|---|

| Soldering & Solderability | IEC60068-2-20 Test Ta |

Temperature: 230±5 ℃, 2-2.5mm away from ceramic body On: 2±0.5 Seconds. |

The terminations shall be evenly tinned |

| Resistant to soldering heat | IEC60068-2-20 Test Tb |

Temperature: 260±5℃, 2-2.5mm away from ceramic body On:10±1 Seconds. |

No visible damage, ΔR25/R25≤3% |

| Lead wire tensile | IEC60068-2-21 Test U |

Test Ua: Force 10N, On 10 Seconds; Test Ub: Bending 90C, Force 5N, Twice. |

No break off, ΔR25/R25≤3% |

| Test | Standard | Test Conditions | ΔR25/R25 (typical) | Remarks |

|---|---|---|---|---|

| Low temperature storage | IEC 60068-2-1 | Storage at low category temperature: -30 oC, Time: 1000 hours |

≤3% | No visible damage |

| Storage in dry heat | IEC 60068-2-2 | Storage at upper category temperature: 200 oC, Time: 1000 hours |

≤3% | No visible damage |

| Storage in damp heat, steady state (Humidity test) | IEC 60068-2-3 | Temperature: 40oC, Humidity:90%-95% RH, Duration:1000 hours |

≤3% | No visible damage |

| Temperature cycling | IEC 60068-2-14 | 1. -30C/30 minutes 2. 80C/5 minutes 3. 200C/30 minutes 4. 80C/5 minutes. Number of cycles: 5 Cycles |

≤3% | No visible damage |

Minimum lead wire length tailored to shall be ≥8mm.

In lead wire bending, bending point shall be more than 2mm away from glass body part.

Mounting and Handling Recommendations

Excessive forces applied to a sensor may cause serious damage. To avoid this, the following recommendations should be adhered to:

- No perpendicular forces must be applied to the body

- During bending, the leads must be supported

- Bending close to the body must be done very carefully

- Axial forces to the body can influence the accuracy of the sensor and should be avoided

- These sensors can be mounted on a minimum pitch of >5 mm

Soldering and Welding

- Avoid any force on the body or leads during, or just after, soldering.

- Do not correct the position of an already soldered sensor by pushing, pulling or twisting the body.

- Prevent fast cooling after soldering.

- For hand soldering, where mounting is not on a printed-circuit board, the soldering temperature should be <300C the soldering time <3 s and the distance between body and soldering point >1.5 mm.

- For hand soldering, dip, wave or other bath soldering, mounted on a printed-circuit board, the

- soldering temperature should be <300C, the soldering time <5 s and the distance between body and soldering point >1.5 mm.

- The distance between the body and the welding point should be >0.5 mm. Care should be taken to ensure that welding current never passes through the sensor.

Other Related AMWEI NTC Thermistors Products for Temperature Sensing

Content Headline

Technical Knowledge

NTC Thermistor Glossary and Definition

How NTC thermistor beta value is calculated?

NTC Thermistor Manufacturing Process and Quality Control

Applications Articles

How to Select NTC Thermistor for Inrush Current Limiting?

NTC thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC thermistor

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select Packaged Thermistor Temperature Sensor Probe Assembly ? 6 Steps