NTC Thermistors Manufacturing Process and Quality Control

NTC thermistor manufacturing starting materials are different oxides of metals such as manganese, iron, cobalt, nickel, copper and zinc, to which chemically stabilizing oxides may be added to achieve better reproducibility and stability of the NTC thermistor characteristics.

The oxides are milled to a powdery mass, mixed with a plastic binder and then compressed into the desired shape. The blanks are then sintered at high temperatures (between 1000 °C and 1400 °C) to produce the polycrystalline thermistor body. Disks are contacted by baking a silver paste onto the flat surfaces. Depending on the application, the thermistors are fitted with leads or tab connectors, coated or additionally incorporated in different kinds of housing. Finally the thermistors are subjected to a special aging process to ensure high stability of the electrical values.

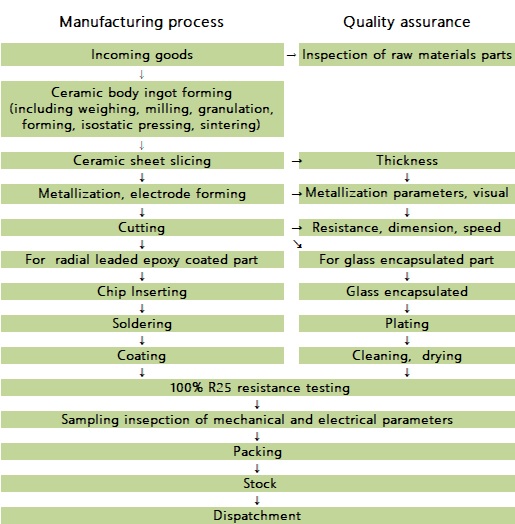

The major production process for temperature measurement Leaded NTC thermistor is as following:

NTC Thermistor Manufacturing Process