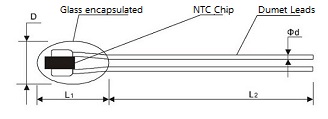

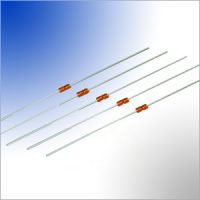

Radial Leaded Glass Encapsulated NTC thermistor Temperature Sensor

Radial Glass NTC Thermistor Sensor

Radial Leaded Glass Encapsulated NTC thermistor features with small dimension, very short response time, heat resistive and highly stable. temperature measurement range -40C to +300C.

·Glass encapsulated, heat-resistive and highly stable.

·Glass body provides hermetic seal & voltage insulation, can operate in high temperature and moisture environment.

·For temperature measurement up to 300C.

·Very short response time.

·Small dimensions.

·Resistance @25C 2k ohm, 10k ohm, 49k ohm, 50k ohm, 100k ohm, 200k ohm,231.5k ohm, etc.

·Tight tolerance on resistance and Beta value.

·Fast heat induction, high sensitivity.

·Leads: dumet wires (copper-clad FeNi)

·Dissipation factor: ≥2.0 mW/C in still air.

·Thermal time constant: ≤6.5 seconds in still air.

- In household electronics temperature measurement, detection and control: micro-wave ovens, electric cookers, induction cooker, voltage cooker, toast, water boiler, coffee maker, etc.

- Medical Industry: electronic thermometer.

- In heating and air conditioning (HVAC): in heating cost distributors, in under-flooring heating and gas boilers, for determining exhaust gas or burner temperature.

- Industrial electronics: for temperature stabilization of laser diodes and photo-elements, for temperature compensation in copper coils or reference point compensation of thermo-elements, etc. Also for temperature measurement and compensation of meters, instruments, integrated circuits, quartz crystal oscillators and thermocouples.

- In telecommunication: for temperature measurement, compensation and control and protection of mobile phones, battery pack and battery charger, etc.

- Radial glass encapsulated package NTC thermistor can also be used in temperature measurement, monitoring, detection and control of food processing equipment, climate, etc.

| Type | D | L1 | L2 | Φd±0.05 |

| Type A | 1.3±0.2 mm | 2.8Max mm | 65±5 mm | 0.2 mm |

| Type B | 1.8±0.2 mm | 3.4±0.5 mm | 65±5 mm | 0.25 mm |

Unit: mm

| AMWEI Part Number | Resistance @25C R25 (K ohm) |

Beta Value (K) |

Specific Temperature Point Resistance Data (ohm) |

|---|---|---|---|

| AMF58B-103□3435(B25/85) | R25: 10K ohm | B(25/85C):3435K | |

| AMF58B-103□3950(B25/50) | R25: 10K ohm | B(25/50C):3950K | |

| AMF58B-49.12K□3970(B0/100) | R25: 49.12k ohm | B(0/100C):3970K | R100: 3.3K ohm |

| AMF58B-503□3950(B25/50) | R25: 50K ohm | B(25/50C):3950K | |

| AMF58B-98.63K□4300(B100/200) | R25: 98.63K ohm | B(100/200C):4300K | R200: 0.55K ohm |

| AMF58B-104□3950(B25/50) | R25: 100K ohm | B(25/50C):3950K | |

| AMF58B-104□4200(B25/50) | R25: 100K ohm | B(25/50C):4200K | |

| AMF58B-204□4200(B25/50) | R25: 200k ohm | B(25/50C):4200K | |

| AMF58B-231.5K□4537(B100/200) | R25: 231.5K ohm | B(100/200C):4537K | R200: 1.0K ohm |

Notes:□ in the part number for filling in resistance tolerance, optional for ±1%(F), ±2%(G), ±3%(H), or ±5%(J).

| Test | Standard | Test Conditions | ΔR25/R25 (typical) | Remarks |

|---|---|---|---|---|

| Low temperature storage | IEC 60068-2-1 | Storage at low category temperature: -30C, Time: 1000 hours | ≤2% | No visible damage |

| Storage in dry heat | IEC 60068-2-2 | Storage at upper category temperature: 200C, Time: 1000 hours | ≤2% | No visible damage |

| Storage in damp heat, steady state (Humidity test) | IEC 60068-2-3 | Temperature: 40C, Humidity:90%-95% RH, Duration: 1000 hours |

≤2% | No visible damage |

| Temperature cycling | IEC 60068-2-14 | 1. -30C/30 minutes 2. 80C/5minutes 3. 200C/30 minutes 4. 80C/5minutes. Number of cycles: 5 Cycles |

≤2% | No visible damage |

| Test | Standard | Test Conditions and methods | Requirements |

|---|---|---|---|

| Soldering & Solderability | IEC60068-2-20 Test Ta |

Temperature: 230±5 ℃, 2-2.5mm away from ceramic body On: 2±0.5 Seconds. |

The terminations shall be evenly tinned |

| Resistant to soldering heat | IEC60068-2-20 Test Tb |

Temperature: 260±5℃, 2-2.5mm away from ceramic body On:10±1 Seconds. |

No visible damage, ΔR25/R25≤2% |

| Lead wire tensile | IEC60068-2-21 Test U |

Test Ua: Force 10N, On 10 Seconds; Test Ub: Bending 90C, Force 5N, Twice. |

No break off, ΔR25/R25≤2% |

Other Related AMWEI NTC Thermistors Product for Temperature Sensing

Content Headline

Radial Glass NTC Features

Application Examples

Dimension

AMWEI Radial Glass NTC Data Sheet

Reliability Data

Mechanical Test

Technical Knowledge

NTC Thermistor Glossary and Definition

How NTC Thermistor beta value is calculated?

NTC Thermistor Manufacturing Process and Quality Control

Applications Articles

NTC thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC Thermistor

How to Select NTC Thermistor for Inrush Current Limiting?

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select Packaged Thermistor Temperature Sensor Probe Assembly ? 6 Steps