Radial Lead Resin Coated NTC Thermistor for Temperature Compensation

NTC thermistor Temperature Compensation

Since all metals used for coil windings have a positive temperature coefficient of resistance, NTC thermistors are especially useful for compensating resistance changes in devices subjected to temperature variations.

Due to the high temperature coefficient of the thermistor as opposed to the low temperature coefficient of the copper, full compensation can be achieved by using a thermistor– resistor network. This network adds less than 15% to the total impedance of the circuit. Compensation of transistor amplifiers, crystal oscillators, etc. can be achieved by using similar methods.

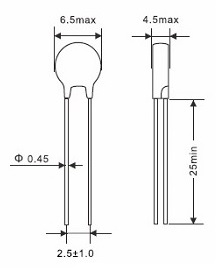

- AMF11 series in radial lead, resin coated form, diameter after coating 6.5mm.

- Wide R25 resistance range from 10 ohm–200k ohm.

- Typical resistance @25C 15 ohm, 100 ohm, 200 ohm, 500 ohm, 1k ohm, 2k ohm,3k ohm, 4k ohm, 5k ohm, 10k ohm, 15k ohm, 20k ohm, 30k ohm, 47k ohm, 50k ohm, 100k ohm, 200k ohm, etc.

- Resistance tolerance can be 5%, 10%, 20%.

- Rated power 0.5W.

- Operating temperature: -55C–+125C.

- Temperature compensation in electronic circuit.

- Temperature compensation of meter,instrument and other computation equipment.

- Temperature compensation of instrumentation winding coil, integrated circuits, crystal oscillator Temperature measurement and control which do not have very high accuracy requests.

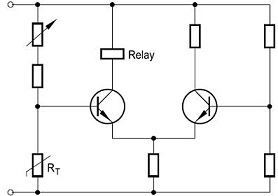

circuit for a thermostat temperature controller, A simple circuit configuration for a thermostat, Circuit for a temperature controller

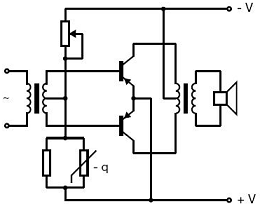

NTC Thermistor Temperature compensation in transistor, Push-pull compensation.

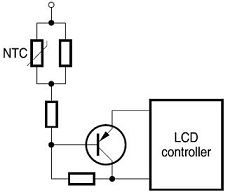

LCD temperature compensation circuit

Temperature Compensation NTC Thermistor Dimension

Schematic drawing of a temperature compensation circuit of Liquid crystal displays (LCDs) using NTC thermistor as temperature sensor

For Liquid crystal displays LCD modules often a temperature compensation circuit is used, consisting of NTC thermistors and resistors. The NTC thermistor as main temperature-sensitive device with its characteristic resistance temperature curve provides a high driving voltage in the cold and a low driving voltage in the hot temperature region, compensating in this way the LCD temperature characteristic.

| AMWEI Part Number | Resistance @25C (R25) |

Beta value B(25/50C) | Dissipation factor (mW/C) |

Thermal time constant (S) |

Operating temperature (C) |

||

|---|---|---|---|---|---|---|---|

| R25 range (Ohm) |

Tolerance (%) |

B(25/50C) (K) |

Tolerance (%) |

||||

| AMF11-□□ | 8-24 | ±5 ±10 ±15 ±20 |

2800 | ±10 | ≥6.0mW/C in still air |

≤30s in still air |

-55~+125C |

| 25-119 | 3000 | ||||||

| 120~359 | 3200 | ||||||

| 360~1400 | 3600 | ||||||

| 1500~5900 | 3950 | ||||||

| 6000~12000 | 4050 | ||||||

| 13000~17000 | 4150 | ||||||

| 18000~44000 | 4250 | ||||||

| 45000~79000 | 4300 | ||||||

| 80000~144000 | 4400 | ||||||

| 145000~199000 | 4500 | ||||||

| 200000~299000 | 4600 | ||||||

| 300000-500000 | 4750 | ||||||

Note: The first □ for filling in Resistance @25C(R25), the second □ for filling in resistance tolerance.

| Test | Standard | Test Conditions | ΔR25/R25 (typical) | Remarks |

|---|---|---|---|---|

| Storage in dry heat | IEC 60068-2-2 | Storage at upper category temperature, Temperature:125C, Time: 1000h | <3% | No visible damage |

| Storage in damp heat, steady state | IEC 60068-2-3 | Temperature of air:40C, Relative humidity of air:93%, Duration: 21 days | <3% | No visible damage |

| Rapid temperature cycling | IEC 60068-2-14 | Lower test temperature:-55C, Upper test temperature: 125C, Number of cycles:100 | <3% | No visible damage |

| Endurance | \ | Pmax:450mW, t:1000h | <3% | No visible damage |

| Long-term stability | \ | Temperature: 125C, Time:10000h | <5% | No visible damage |

Content Headline

NTC Thermistor Glossary and Definition

How NTC thermistor beta value is calculated?

NTC Thermistors Manufacturing Process and Quality Control

Applications Articles

How to Select NTC Thermistor for Inrush Current Limiting?

NTC thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC Thermistor

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select Packaged Thermistor Temperature Sensor Probe Assembly ? 6 Steps