PTC Thermistors as Heating Elements Disk Shaped, 220V 270C Diameter 20mm R25: 2K-10K Ohm

AMWEI Ordering Code: PHD20X2MM220V270C

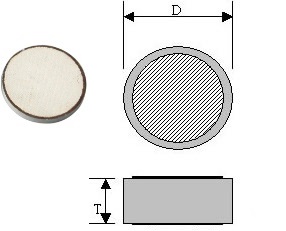

Appearance and Dimension

PTC Heater Disk

- Diameter D : 20±0.5mm .

- Thickness T: 2.0±0.2mm

- Flatness Curvature <0.1mm

- Electrode: Silver Metallization

Electrical Specifications

- Resistance @25C R25 : 2k-10k Ω

- Rated voltage (RMS) : 220 V

- Maximum operating voltage Vmax: 265 V

- PTC Thermistor Surface Temperature: 270C±10C

- Operating ambient temperature range (V=0): -40~+200C

- Operating ambient temperature range (V=Vmax) : -40~100C

Application

Applied for 220V/120V heating, can be used in tool equipment vehicles cabin battery motor heating, etc.

Reliability Data

| Test Item | Standard | Test conditions | |ΔR25/R25| |

|---|---|---|---|

| Electrical endurance, cycling |

IEC 60738-1 | Room temperature, Vmax Number of cycles: 10000 |

<25% |

| Electrical endurance, constant |

IEC 60738-1 | storage at Voltage: 220V Ambient temperature: +100C Test duration: 1000 h |

<25% |

| Damp heat | IEC 60738-1 | Temperature of air: 40 °C Relative humidity of air: 93% Duration: 56 days Test according to IEC 60068-2-78 |

<25% |

PTC Heater Chips Round Ring Rectangular Honeycomb

Wire Soldered Silicon Coated Insulated PTC Heaters

Metal Housing Conductive Heater

Cartridge Heaters Threaded Al Metal

Flow through Liquid Water Heater

Build-in Liquid Water Heater

PTC Air Heater

Convection Anti-Freeze Anti-Damp

PTC Diesel Fuel Heater

Technical Information

PTC Thermistors Glossary and Definition, 3 PTC Thermistors Characteristics, Resistance vs. Temperature RT Characteristic, Voltage vs. Current VI characteristic, Current vs Time Characteristic.

PTC Thermistors Application Cautions for Soldering, Mounting, Cleaning.

PTC Thermistors Manufacturing and Quality Control

The Advantage of Using PTC Thermistors as Heating Elements and Application Precaution

Dimensioning PTC Thermistors

Consideration Factors in Designing PTC thermistors as Heater

Selection Criteria for PTC Heating Thermistors