PTC Thermistors Heaters

PTC Heater characteristic

PTC Heater is ceramic barium titanate PTC thermistor used for self-regulation constant heating, no glowing parts, no overheating, energy efficient, compact design, long service life.

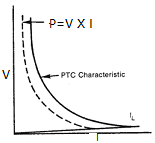

PTC thermistor positive resistance vs. temperature R/T characteristic means that electric power consumed is automatically adapted to the ambient thermal conditions. At an ambient temperature significantly lower than Tref, i.e. with good heat transfer, the PTC thermistor has low resistance and consumes a relatively large amount of power. If the ambient temperature is significantly higher than Tref or heat transfer is restricted, the resistance of the PTC thermistor rises rapidly and power consumption is limited to a very low value.

Thanks to self-regulation properties, heating devices based on PTC thermistor technology can generally dispense with control and regulating components as well as with over-temperature protection, PTC thermistor heating elements are used wherever measurement and regulating equipment as well as heating devices must be housed in tight confines. There are no glowing parts, because the maximum surface temperature is limited by the R/T curve.

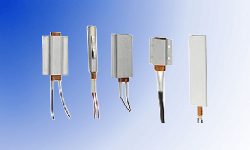

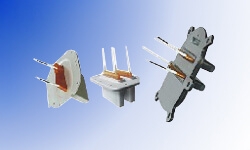

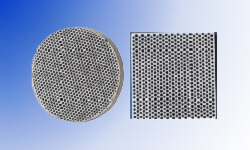

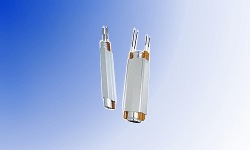

PTC thermistor heating pellet elements can be designed to be square, rectangular, disc round, ring or doughnut form, or PTC stone housed in aluminum, stainless steel, silicon casing.

- Safe through temperature limiting characteristics.

- No danger of fires since there are no glowing parts.

- Dynamic, self regulating, and therefore energy efficient.

- No excess temperature protection required.

- Voltages from 6V to 480 V; special voltage applications up to 800 V.

- PTC thermistor surface temperatures can be set from 50C to 320C.

- Compact design.

- Long service life.

- Household appliance: travel irons, travel jug, bread warmer, water heater, water evaporator, espresso and coffee machine, tea warmer, dishwasher, ice makers, mosquito killer, insecticide, room deodorants, dryer, dehumidifier, plug-in aroma heater, fragrance, liquid vaporizer, cabinet heater, keep-warm plates, bimetal heater for door latches of washing machine, bathroom heater, etc.

- Hair care: hair curler, hair crimper, hair drier, curling brush, steam curler, curling irons, curling tongues, hot comb.

- Body care: wax depilators, facial sauna, inhalators, cosmetic warmers, ultrasonic bath, other heating of laminary case.

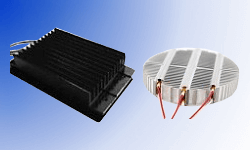

- HVAC application: PTC fan heater, air heater, air curtain, electric air fresheners, air pre-conditioning.

- Industrial appliances: oil-preheating, boiler-preheating, frost protection, valve heating, mould heating, binding system, laminator, hot glue gun, switch cabinet heaters, Anti-condensation, engine preheating, plastic film welder.

- Automotive appliance: vehicle interior heating, fuel preheating, diesel filter heating, crankshaft housing ventilation, nozzle heaters for windshield washers, steering wheel heater, additional cabin heating.

- Medical application: Inhalers, Vaporizer, Heating of anesthesia gas, massage.

- Electronics application: IC heater, video monitor system heating, TCXO heater, Liquid Crystal display, Bimetal heater, CCTC Camera Housing, Display Boards.

- PTC thermistor heating elements can also be used in Instrumentation heater, Contact lens cleaner, telecommunication enclosure cabins heater, laboratory equipment, apparatus construction, viscosity of a liquid needs to be tightly controlled, such as printing.

PTC thermistors are ideal as heating elements because of their specific R/T characteristic. The positive R/T characteristic means that electric power consumed is automatically adapted to the ambient thermal conditions.

At an ambient temperature significantly lower than Curie temperature Tref (also switch temperature or reference temperature ), i.e. with good heat transfer, the thermistor has low resistance and consumes a relatively large amount of power.

If the ambient temperature is significantly higher than Tref or heat transfer is restricted, the resistance of the thermistor rises rapidly and power consumption is limited to a very low value.

Thanks to these self-regulation properties, heating devices based on PTC thermistors can generally dispense with control and regulating components as well as over-temperature protection. So PTC thermistor heating elements are used wherever measurement and regulating equipment as well as heating devices must be housed in tight confines.

There are no glowing parts, because the maximum surface temperature is limited by the R/T curve. In heating applications the PTC thermistors are operated directly at the available voltage without a series resistance, preferably in the low-resistance section of the R/T characteristic, since particularly high heating power is achieved in this section of the curve.

To make use of this advantage, it is important to create conditions that will not cause the PTC thermistor to raise its resistance.

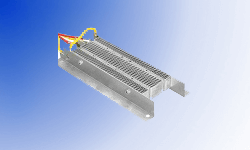

This is ensured with extremely thin PTC thermistors by increased heat transmission from the surface.

To this end, the PTC thermistor is placed between heat-emitting solid bodies to optimize heat flow from the thermistor to the environment to be heated. Here, symmetrically thermal decoupling is of great advantage.

Special care has to be taken when PTC thermistors are used in potted circuits. The high thermal resistance of potting materials can very much impair heat transmission so that the PTC thermistors could heat up to a critical temperature level. In PTC thermistors operated at line voltage, steep temperature gradients and sometimes high operating temperatures are generated in the heating-up phase. In these cases soldering should be avoided since the solder joints may fatigue. The devices can be offered with a metallized surface for clamp contacting, which guarantees favorable thermal decoupling.

The electrically absorbed power of the PTC thermistor equals the thermal dissipated power:

PTC power equation

- Rth thermal resistance in K/W

- Tsurf,PTC surface temperature of PTC thermistor

- TA ambient temperature

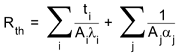

The thermal resistance Rth depends on the dimensions and the thermal conductivity of the PTC and the contact electrodes, as well as the heat transfer coefficient of the surrounding media (e. g. air).

For maximum heat output, the thermistor must be mounted in a plane configuration so that minimum thermal resistance is obtained.

The following equation can be generally applied to calculate the thermal resistance Rth:

PTC thermal resistance calculate equation

- α heat transfer coefficient in W/(cm² . K)

- A cross-sectional area of material transferring heat

- t layer thickness in cm

- λ thermal conductivity in W/(cm . K)

This means that the power dissipation of a heating PTC depends not only on the properties of the PTC thermistor itself but also on the heat transfer coefficient and geometry of the clamping contact, as well as on the surrounding medium and its temperature. This should be taken into account in the design of the heating assembly and for the selection of the PTC .

AMWEI PTC Heater Products Examples

- PTC Thermistors Heater Disk 220V 270C Diameter 20mm R25 2K-10K Ohm

- PTC Heater Disk 12V 130C 9 Ohm Diameter 13mm

- PTC Heater Disk 230V 200C 8X3mm

- PTC Heater Rectangular 230V 160C 1k ohm 35X6X2.54mm

- PTC Heater Rectangular 230V 125C 1k ohm 35X6X2.54mm

- PTC Ceramic Thermistor Heater 110V 220V 260C 24x15X2.5mm Rectangular Clamp Contact

- PTC Heater Ring 220V 110C Diameter Diameter Outer 14.5mm, Inner 4.3mm R25: 100-1000 Ohm

- PTC Thermistor Heater 220V 110V 180C Polyimide Kapton 3 Wraps Insulated 24x15x3.2mm 100mm Cable

- PTC Thermistor Surface Heater 110V/220V 260C Aluminium Housing Flanged With Mounting Holes

- Threaded Aluminum Housing Φ3.5×30 + M8×1.25 mm 12V 160C PTC Cartridge Heater Assembly

- Fluid Pass Through PTC Liquid Water Heater 220V 800W Al Housing

Content Headline

What Is PTC Heater ?

AMWEI PTC Heater Products

PTC Thermistor Heater Features

PTC Heater Application

The Advantage of Using PTC Thermistor as Heating Elements and Application Precaution

Dimensioning PTC Thermistors

Technical Information

PTC thermistors Glossary and Definition

3 PTC thermistors characteristics, Resistance vs. Temperature RT Characteristic, Voltage vs. Current VI characteristic, Current vs Time Characteristic.

PTC thermistors Application Cautions for Soldering, Mounting, Cleaning.

PTC thermistors Manufacturing and Quality Control.

Consideration Factors in Designing PTC thermistors as Heater

Selection criteria for PTC heating thermistors

FAQ PTC Heater

PTC thermistor, made from doped BaTiO3 ceramic material, is ideal heating element due its specific positive R/T characteristic, self-regulating, no glowing parts, no overheating, energy efficient, compact design, long service life.

PTC Thermistors as Heaters has the following advantage, compared with other heating elements:

- No overheat, Safe through temperature limiting characteristics.

- No danger of fires since there are no glowing parts.

- Dynamic, self regulating, and therefore energy efficient.

- No excess temperature protection required.

- Voltages from 6V to 480 V; special voltage applications up to 800 V.

- PTC thermistor surface temperatures can be set from 50C to 320C.

- Compact design.

- Long service life.

In selecting PTC Heater chips stone, please specify:

- Surface temperature or Switch temperature.

- Outlook and dimension.

If in disc form, inform the diameter and thickness.

If in rectangular form, inform the length, width, and thickness.

Or inform how many spaces you can leave for PTC heater. - Operating voltage

- Resistance @25 Centigrade R25 and its tolerance.

In selecting metal housing conductive cartridge PTC thermistors heater assembly, please specify:

- Housing material and Dimension, or how many space can you leave for PTC heater assembly?

- Operating voltage

- Powerwatt

- PTC heater surface temperature,

Please specify whether it is PTC heater surface temperature with input of operating voltage.

Or it is the temperature of your fixed assembly device temperature.