Soldered Coated Insulated Metal Housing Conductive PTC Heater

PTC thermistors heater chips with silver metalization can be soldered with pin wire, ceramic body coated with resin, or non-coated, most used for lower temperature heating environment.

Typical application for PCB boards anti-freezing, anti-dewing, anti-moisture. Can be soldered directly on PCB boards, small size, less energy consumption.

Typical switch temperature 80C, 100C, 120C.

Ceramic body diameter 5mm, 7mm, 8mm, 10mm, 12mm, 16mm, 20mm.

Resistance @25C: 3 0hm to 3000 ohm.

Soldered Coated PTC Heater

Single Soldered PTC Heater

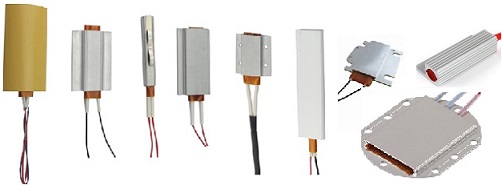

Insulated PTC Heater

PTC chips metallized surface for clamp contacting, which guarantees favorable thermal decoupling. Insulated wrapped, Polyimide insulation used for higher temperature application. Available for surface and spot heating.

For lower temperature application, PET, PU can also be used for insulation.

Surface Temperature: 50℃~280℃

Operating voltage 12V~240V

Example:

PTC Thermistor Heater 220V 110V 180C Polyimide Kapton 3 Wraps Insulated 24x15x3.2mm 100mm Cable

PTC thermistors can be housed in aluminum case or other metal for surface and spot heating. The metal housing can be designed with mounting holes for easy installation. Metal Housing Conductive PTC heating elements need very little mounting space and feature a high power density.

Conductive heating elements are available as heating profiles (HP) and heating discs (HT).

Surface Temperature: 50℃~280℃

Operating voltage 12V~240V

Insulation voltage can be 3750V/0.5mA/1seconds

Applications

Ultrasonic Cleanser, Steam Cooker, Ski Boot Dryer, Glue Guns, Control Valves

Heating, etc.

Metal Housing PTC Heater

PTC Heater Chips Round Ring Rectangular Honeycomb

PTC Heaters with Wire, Single Solder, Silicon Coated, Insulated

Metal Housing PTC Conductive Heater

PTC Cartridge Heaters, Threaded Al, Metal Tube

Flow through PTC Liquid Water Heater

Build-in PTC Liquid Water Heater

PTC Air Heater

PTC Convection Heaters Anti-freeze Anti-damp

PTC Diesel Fuel Heater

Technical Information

PTC Thermistors Glossary and Definition, 3 PTC Thermistors Characteristics, Resistance vs. Temperature RT Characteristic, Voltage vs. Current VI characteristic, Current vs Time Characteristic.

PTC Thermistors Application Cautions for Soldering, Mounting, Cleaning.

PTC Thermistors Manufacturing and Quality Control

The Advantage of Using PTC Thermistors as Heating Elements and Application Precaution

Dimensioning PTC Thermistors

Consideration Factors in Designing PTC thermistors as Heater

Selection Criteria for PTC Heating Thermistors