PTC Thermistors

PTC thermistors RT Characteristics linear silicon vs switching ceramic

PTC thermistor is thermally sensitive semiconductor resistor, Resistance increases with temperature rising, fall into 2 major categories,

- Silicon Resistors , Silistor exhibit a fairly uniform positive temperature coefficient (about +0.77%/C) through most of their operational range, often used for temperature measurement and temperature compensation.

- Switching Ceramic PTC thermistors, CPTC made of doped polycrystalline ceramic on the basis of barium titanate, major material BaTio3. The resistance rises sharply at Curie temperature. Used for overload overcurrent protection, temperature sensing protection, self-regulating heating, motor starting, motor protection, lighting soft starting, etc.

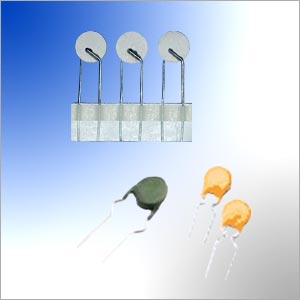

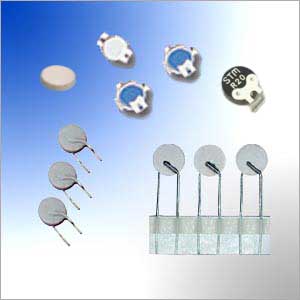

AMWEI PTC Thermistors Products Lineup

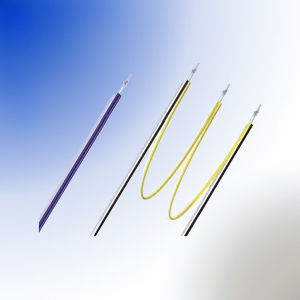

AMWEI Linear Silicon PTC thermistors Temperature Sensors Silistors, axial glass DO35 package, KTY84 KTY83 KTY81 substitute, R25 600, 1000, 2000 ohm, resistance increases with the temperature rises in linearity, the silicon temperature sensors exhibit fail-safe operation when a system overheats. Furthermore silicon is inherently stable, so silicon temperature sensor is extremely reliable, has very long operational lifetimes, widely applied in temperature sensing and control in drives and motors, equipment, industrial automation control, etc.

PTC Thermistors Circuit Protector, also called PTC Thermistors Resettable Fuse, are used instead of conventional fuses to protect load, such as motors, transformers, or electronic circuit, against overcurrent for circuit protection. PTC thermistors over-current protector limits the power dissipation of the whole circuit by increasing their resistance and thus reducing the current to a harmless residual value. In contrast to conventional fuses, PTC thermistors resettable fuses do not have to be replaced after elimination of the fault but resume their protective function immediately after a short cooling-down time.

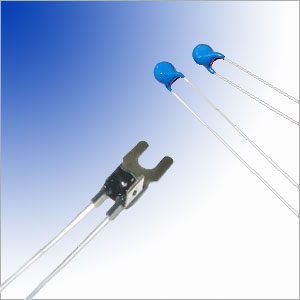

PTC thermistors help provide protection against power cross, power induction surges and lighting surge defined in ITU, Telcordia, UL. Available in disk, radial-leaded coated and non-coated configuration. This thermally sensitive semiconductor resistor provides reversible, self-resetting fuse protection against over-currents short circuit for telecommunication line protector units, improve the reliability of custom premises and network equipment.

Making use of the characteristics that the resistance of PTC thermistors increases sharply above curie temperature, when ambient temperature increases abnormally, protective circuit installed PTC thermistors will turn on or cut off loop through resistance changing, achieving thermal protection purpose.

PTC thermistors can protect equipment motors transformers power transistors thyristors against over-temperature, in radial epoxy, metal tag lug, or screw threaded metal cases.

PTC thermistors with their very steep curves are very suitable for the monitoring of temperature limits and consequently for switching on a fan when a particular temperature is reached. Over-temperature sensing of windings in electric motors, coils, transformers, equipment, machines, etc. Conform with DIN 44081, 44082, featured with steep R/T curve, small dimensions.

PTCR Motor start packages can be economical solid state torque assist for heat pumps, room air, commercial and residential air conditioning and refrigeration systems. PTC thermistor can be used to protect the auxiliary starter winding of induction motors or single phase motors.

Compared to the alternative start capacitor and relay, PTCR Motor start devices save several wires, occupy less panel space, mount more easily, and cost less.

Lighting Switching PTC thermistor are used when a load in series with the PTC thermistor has to be switched off after a time delay and when switching occurs frequently.

A typical application of switching PTC thermistor is the preheating of electrode in energy-saving lamps or fluorescent lamps. Switching PTC thermistor can also be used as a power resistor for loading a capacitor, for example in power supplies or in control units of production equipment.

Technical Knowledge

PTC Thermistors Glossary and Definition

3 PTC Thermistors Characteristics, Resistance vs. Temperature RT Characteristic, Voltage vs. Current VI characteristic, Current vs Time Characteristic.

PTC thermistors Application Cautions for Soldering, Mounting, Cleaning.

PTC Thermistors Manufacturing and Quality Control.

Applications Articles

How to select PTC thermistor for overcurrent overload protection?

PTC Thermistors Meter Test Measuring Instrument Protect.

PTC Thermistors Telecom Equipment installation Protect, Ceramic vs. Polymer.

PTC Thermistors Protect Converters MOSFET from Overheating

PTC Thermistors Limit Temperature Sensor for thermal monitoring makes hot spots under control