PTC thermistors Limit Temperature Sensor Thermal Monitoring Makes Hot Spots Under Control

Thermal management is becoming increasingly important as a result of miniaturization, rising power consumption and tougher requirements on reliability. At the same time the number of hot spots on boards and equipment is also growing. These are points where critical temperature rises must be expected.

1. PTC Thermistor Characteristics Temperature vs. Resistance Curves

Among the typical applications that require the monitoring of several hot spots are computers such as servers and notebooks, industrial equipment such as large power supplies, UPS systems, frequency converters, lighting controllers as well as automotive electronics systems. The hot spots at which excess temperatures can occur as a result of power dissipation are often found on power semiconductors such as MOSFETs or IGBTs. Other possible locations include inductors, transformers, capacitors and motors.

PTC Thermistors Limit Temperature Sensor have a nonlinear characteristic: at low temperatures such as ambient, their resistance is low. As the temperature rises, their resistance jumps suddenly depending on the ceramic material used. This threshold value is also known as the reference or limit temperature.

Figure 1 shows the typical characteristic of a PTC thermistor.

At normal temperatures, the PTC thermistor sensor has a low resistance with a typical value of less than 1k ohm. As the temperature rises, however, its resistance begins to increase. When the specified limit temperature TSense is reached, its resistance jump with respect to the temperature rise. This sudden increase in resistance makes PTC thermistors ideal as limit temperature sensors, allowing them to detect the critical temperature of sensitive electronic components in good time. For this purpose, they should be mounted as close as possible to the component they are designed to protect. This assures good thermal contact as well as a fast response time.

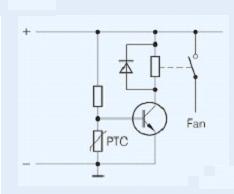

2. PTC thermistor detecting over temperatures circuit

As shown in Figure 2, the PTC thermistor sensor is normally inserted together with a fixed resistor into a voltage division circuit. This results in a temperature-dependent output voltage Vout, which changes suddenly according to the characteristic of the PTC sensor and directly controls a component such as a switching transistor or comparator. This in turn triggers corresponding functions in order to avoid overheating and consequent damage. In this way, a blower can be switched in or loads and system components switched off very cost effectively.

This simple circuit can be used to monitor a single hot spot cost-efficiently and reliably.

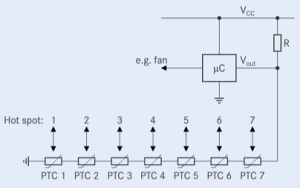

PTC thermistors temperature measurement at several hot spots

PTC Thermistors Temperature Measurement at several hot spots

The steep and rapid change in resistance of PTC thermistor sensors with temperature allows several hot spots to be monitored with a simple circuit. For instance, if seven different points have to be monitored simultaneously on a circuit board or in an item of equipment, the circuit shown in Figure 3 is an obvious choice. A single PTC is located at every point to be monitored. Thanks to their steep characteristic, all PTC thermistors can be connected in series while assuring reliable monitoring of each individual hot spot.

Despite the series circuit, reliable measurement of over-temperatures is possible at each hot spot. This circuit topology permits cost-effective, space-saving and reliable temperature management.

This circuit can be used for the systems such as power supplies, UPS, frequency converters, servers, light controllers and systems of automotive electronics. Very often, the hot spots at which power losses can lead to the occurrence of over-temperatures are power semiconductors such as MOSFETs or IGBTs, but they may also be inductors, transformers, capacitors and motors, etc.

Related AMWEI PTC Thermistors Products

Linear Silicon PTC Thermistor Temperature Sensor

PTC Thermistor Current Protect Resettable Fuse

PTC thermistor for High Voltage Current Surge Telecom Protect

PTC Thermistor Limit Temperature Sensor

Lighting Switching Time Delay

PTC Motor Sensor, 1 PTC Single Sensor & 3 PTCs triple Sensor

PTC Thermistor Motor Starter