PTC Thermistors for Overcurrent Overload Protection in Telecom Applications, Leaded Disk Coated 25 Ohm 250V 1A

Ceramic PTC thermistor help telecom equipment provide protection against power cross, power induction surges and lighting surge defined in ITU, Telcordia, UL. Compliant with ITU-T K20 K21 K45. Suitable for continuous connection to main voltage 110/230 VAC in tripped (high ohmic) condition. Negligible resistance drift after soldering or switching.

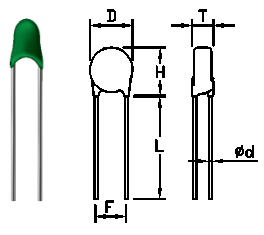

AMWEI PTC Thermistor for Telecom Overcurrent Protection Leaded Disk Coated Outlook Dimension

Leaded Coated PTC Telecom Protect Outlook Dimension

- Silicon resin coated ceramic body, green color

- Coated ceramic body outer diameter D : 6.5mm max.

- Coated ceramic body thickness T: 5.0mm max.

- Pin wire diameter d: 0.6mm

- 2 Tinned pin wire space F: 5.0± 1mm

- Pin wire length L: 25mm min.

- Coated ceramic body to wire length H: 9.0mm max.

AMWEI PTC Thermistor for Telecom Overcurrent Protection Leaded Disk Coated Application

Overcurrent protection for telecom applications

Suitable for line card applications e.g. POTS, access networks,

customer premises equipment (CPE) or integrated voice data (IVD)

AMWEI PTC Thermistor Telecom Overcurrent Overload Protection Features

Compliant with ITU-T standards

- basic-level lightning surges (10/700 µs)

- basic level power induction (600 V, 1 A, 0.2 s)

- power contact criteria A/B (230 V, 15 min.)

Matching available with narrow resistance tolerance.

Tight resistance matching maintained after switching.

Negligible resistance drift after soldering or switching.

Cross to EPCOS obsolete B59069B1120A051, GE RL1605-25-120-50-PTF.

AMWEI PTC Thermistor Telecom Overcurrent Protection Electrical Specifications

- Resistance @25C R25 : 25Ω,

- Standard R25 tolerance +/- 20%, tight tolerance +/- 15% can be supplied upon request.

- Rated voltage (RMS) : 230 V

- Maximum operating voltage Vmax: 250 V

- Maximum withstanding voltage: 350V

- Maximum permissible repetitive turn over current Imax: 1 A

- Non-trip Current at +25C : 85 mA

- Non-trip Current at +40C: 75 mA

- PTC Thermistor Trip Current, Operating Current at +25℃ It : 170 mA

- Tripping time at +25C: 1A→ 0.5A: < 0.7 seconds.

- Operating ambient temperature range (V=0): -40~+125C

- Operating ambient temperature range (V=230V) : 0~60C

AMWEI PTC Thermistor Telecom Overcurrent Protection Reliability Data

| Test Item | Standard | Test conditions | |ΔR25/R25| |

|---|---|---|---|

| Electrical endurance, cycling |

IEC 60738-1 | Room temperature, 1A; 230V Number of cycles: 100 |

<25% |

| Electrical endurance, constant |

IEC 60738-1 | storage at Voltage: 230V Ambient temperature: +60C Test duration: 1000 h |

<25% |

| Damp heat | IEC 60738-1 | Temperature of air: 40℃, Relative humidity of air: 93%, Duration: 56 days Test according to IEC 60068-2-78 |

<10% |

| Lead wire tensile | IEC60068-2-21 | Test Ua: pull strength 10N, 10 seconds, Test Ub: bending 90°, pull strength 5N, successively twice. Test Uc: revolving 180°, successively twice. |

<20% |

| Rapid change of temperature |

IEC 60738-1 | T1 = Top,min (0 V), T2 = Top,max (0 V) Number of cycles: 5 Test duration: 30 min Test according to IEC 60068-2-14, test Na |

<10% |

| Climatic sequence | IEC 60738-1 | Dry heat: T = Top,max (0 V) Test duration: 16 h Damp heat first cycle Cold: T = Top,min (0 V) Test duration: 2 h Damp heat 5 cycles Tests performed according to IEC 60068-2-30 |

<10% |

AMWEI PTC Thermistor for Telecom Overcurrent Protection Leaded Disk Coated Packaging

Production tape package or loose bulk in plastic package.