PTC NTC Thermistors for Motor Temperature Sensing Protection

Thermistor motor protection

Thermistors can be found wide application in motors, from motor starter, temperature sensing, temperature protection, current protection, etc.

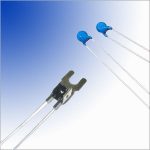

PTC Thermistors for Motor Sensing Temperature Protection

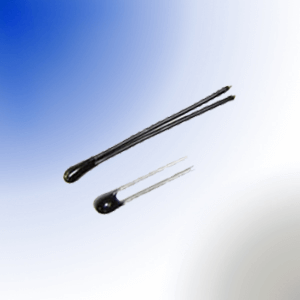

NTC Thermistors for Motor Temperature Sensing

Current Protection Thermistors

Silicon PTC Thermistor resistance increases with the temperature rises in linearity, displays a virtually linear positive temperature coefficient over their entire temperature range.

Silicon temperature sensors exhibit fail-safe operation when a system overheats. Furthermore silicon is inherently stable, so silicon temperature sensor is extremely reliable, has very long operational lifetimes.

Silicon PTC Thermistors

Temperature Sensor is widely applied in motion control temperature sensing, in drives and motors, spindles, inverters and control systems temperature sensing and controls.

For AMWEI PTC Thermistors resistance @ 25C R25 1000 ohm, 2000Ω resistance @100C R100 1000 ohm part, replacement to obsolete NXP KTY81 83 84 series.

PTC Thermistors Circuit Protector, also called PTC Thermistor Resettable Fuse, are used instead of conventional fuses to protect motors against overcurrent for circuit protection. PTC thermistor over-current protector limits the power dissipation of the whole circuit by increasing their resistance and thus reducing the current to a harmless residual value. In contrast to conventional fuses, PTC Thermistor resettable fuses do not have to be replaced after elimination of the fault but resume their protective function immediately after a short cooling-down time.

PTC Thermistors are widely employed as temperature sensors in electrical machines to monitor winding temperature. In this case, the PTC Thermistor is wound directly into the winding so that direct thermal contact is produced. The abrupt increase in the resistance of the thermistor at high temperatures can be used as a control signal for the tripping unit. To detect the temperature at several phases, thermistors should be connected in series. AMWEI offers standard single and triple sensor versions as well as custom assemblies, conform to DIN 44081 and DIN 44082. Available sensing temperatures range from 60 to 190C.

With PTC Thermistors as temperature sensors only the steep region of the R/T characteristic is used. The resistance of the PTC thermistor is to be regarded as a function of the ambient temperature [RPTC = f (TA)]. The precondition for this relationship between resistance and ambient temperature is that selfheating and/or the varistor effect are excluded. This means that these PTC thermistors must be operated in the lowest possible field strengths. To enable a fast response, thermistor sensors have especially small dimensions. High control accuracy is achieved by using materials with an extra steep resistance/temperature characteristic.

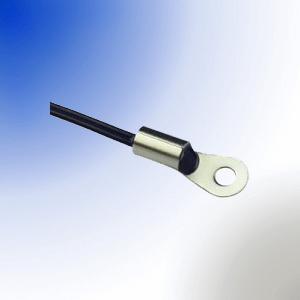

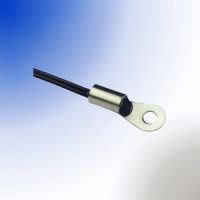

Ring lug NTC thermistor surface temperature probes are designed for screw-in-place mounting, popular for temperature measurement, control, and monitoring of small motors, Thermistor housed in eyelet nickel plated copper material, Good thermal coupling through metal tag. Metal contact surface yields fast temperature response.

Standard ring hole diameter 4.0mm, 3.2mm, resistance @25C 10k ohm, 100k ohm.

Used on a starter generator to provide temperature measurement of the motor coil. Typically mounted on the neutral bar, it detects increases in current that would indicate a failure that could lead to a stall. The sensor can also be used to monitor the motor windings temperature and warn of an over-temperature conditions.

Electric motors exhibit excessive inrush currents when they are turned on, meaning that other components may be damaged or fuses may be tripped. With NTC thermistor, it is possible to effectively limit these currents, by connecting a thermistors in series with the load.

The NTC thermistor specially developed for this application limit the current at turn-on by their relatively high cold resistance. As a result of the current load the thermistor heats up and reduces its resistance by a factor of 10 to 50; the power it draws reduces accordingly.

NTC thermistors are able to effectively handle higher inrush currents than fixed resistors with the same power consumption. NTC thermistor thus provides protection from undesirably high inrush currents, while its resistance remains negligibly low during continuous operation.

An NTC thermistor is always connected in series with the load to be protected. If the inrush current cannot be handled by one thermistor alone, two or more thermistor elements can be connected in series.

Power thermistor components can also be used for the soft starting of motors, for example in vacuum cleaners with continuous currents of up to 20 A.

Single-phase induction motors (e.g. in compressors for refrigerators and air conditioners) can effectively be started when an auxiliary coil is used in the starting phase. The auxiliary coil is cut off from the circuit after the starting phase. For this purpose PTC Thermistors are employed. When high voltage is applied to the PTC thermistor, the high current causes the PTC to heat up and eventually the resistance to increase. A high current flows initially (starting phase) and then decreases in relation to the increase in resistance. After the starting phase (at times >> tS), a low residual current flows through the auxiliary coil.

In a simple starter circuit for single-phase AC motors, the PTC Thermistor is used for delaying the switch-off of the starter auxiliary winding (after the motor has accelerated) to protect the winding from damage.

Thermistors Application

Technical Information

AMWEI PTC Thermistors Manufacturing Process and Quality Control

PTC Thermistors Glossary Definition.

PTC Thermistors Protect Converters MOSFET from Overheating

PTC Thermistor Limit Temperature Sensor for thermal monitoring makes hot spots under control

PTC Thermistor Meter Test Measuring instrument Protect.

What difference between Positive and Negative Temperature Thermistors?

PTC Thermistors Application Cautions for Soldering Mounting Cleaning.

How to Select PTC Thermistor for Overcurrent Overload Protection?

NTC Thermistor Glossary Definition.

AMWEI NTC Thermistor Manufacturing Process and Quality Control.

How NTC Thermistor beta value is calculated?

How to Select NTC Thermistor for Inrush Current Limiting?

NTC Thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC Thermistor

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select NTC Thermistor for Inrush Current Limiting?