Thermistors for Meter Testing Measurement Equipment

Silicon PTC thermistor resistance increases with the temperature rises in linearity, displays a virtually linear positive temperature coefficient over their entire temperature range. Features with fail-safe operation when a system overheats. Furthermore silicon is inherently stable, so silicon temperature sensor is extremely reliable, has very long operational lifetimes.

For AMWEI PTC thermistors resistance @ 25C R25 600, 1000, 2000 ohm part, replacement to obsolete NXP KTY81 83 84 series.

The input circuitry of digital multimeters and other instrumentation requires overcurrent protection against the unintentional fault conditions which can occur.

PTC thermistors offer reliable, convenient and cost-effective protection. Solid state construction allows resettable operation, eliminating the inconvenience of fuse replacement.

Modern multimeters, with wide-ranging functions, are particularly at risk. The inadvertent application of a voltage source to an instrument in resistance mode will cause excessive currents within the input circuitry. Multi-channel instruments, such as oscilloscopes, are also susceptible if the ground terminals are raised to high potential. These high currents, if unchecked, would destroy the input circuitry.

The PTC thermistor is connected directly in series with the input terminals. It is chosen so that over the expected range of working conditions (current, voltage, ambient temperature) the device remains in a low resistance state, offering as little series resistance as possible to ensure accurate measurement.

When a fault condition occurs, the abnormally high current causes sufficient I2R heating in the PTC thermistor to switch it from low to high resistance, reducing the circuit current and preventing damage.

After removal of the fault condition, the PTC thermistor reverts to low resistance to normal operation. Devices can be chosen to achieve automatic reset (fault condition must be removed) or manual reset (power source disconnected).

Making use of the characteristics that the resistance of PTC thermistor increases sharply above curie temperature, when ambient temperature increases abnormally, protective circuit installed PTC thermistor will turn on or cut off loop through resistance changing, achieving thermal protection purpose. PTC thermistor protect equipment against over-temperature. A PTC thermistor is less expensive than a thermostat, and its switch temperature can be more accurately specified. It is also smaller and easier to design-in to electronic circuitry. Therefore PTC thermistor can be ideal devices for temperature detection, monitoring, indicating, limiting and over (excessive) temperature protection.

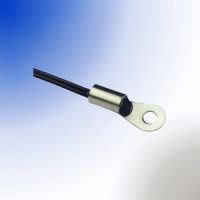

Ring lug NTC thermistor surface temperature probes are designed for screw-in-place mounting, popular for temperature measurement, control, and monitoring of small motors, NTC thermistor housed in eyelet nickel plated copper material, Good thermal coupling through metal tag. Metal contact surface yields fast temperature response.

Standard ring hole diameter 4.0mm, 3.2mm, resistance @25C 10k ohm, 100k ohm.

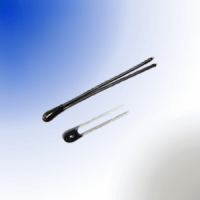

Epoxy Resin coated form, standard pin wire is wire is non-insulated copper brass wire, or steel wire. Optional for insulated PVC wire. Applied in temperature sensing, measurement, monitoring, control, operating temperature range -45C to +125C, R25 1kΩ–150k ohm.

Power NTC thermistor can be a cost effective device to limit the amount of inrush current in a switching power supply or other devices when the power is first turned on. Power NTC thermistor limits surge current by functioning as a power resistor which drops from a high cold resistance to a low hot resistance when heated by the current flowing through it.

Inrush-current limiters power NTC thermistor protect circuits from undesirably high currents, suppressing high inrush current surges, while its resistance remains negligible low during continuous operation. Thanks to their low resistance in the operating state, Power NTC thermistor have a considerably lower power dissipation than the fixed resistors frequently used for this application.

Thermistors Application

Thermistors for Motor Sensing Protection

Transformer Power Supply Protection

HVAC Refrigerator Air Conditioner

Industrial Process Control

Food Cooker Probe Home Appliance

Vehicle Application

Technical Information

AMWEI PTC Thermistors Manufacturing Process and Quality Control

PTC Thermistors Glossary Definition.

PTC Thermistors Protect Converters MOSFET from Overheating

PTC Thermistor Limit Temperature Sensor for thermal monitoring makes hot spots under control

PTC Thermistor Meter Test Measuring instrument Protect.

What difference between Positive and Negative Temperature Thermistors

PTC Thermistors Application Cautions for Soldering Mounting Cleaning.

How to Select PTC Thermistor for Overcurrent Overload Protection?

NTC Thermistor Glossary Definition.

AMWEI NTC Thermistor Manufacturing Process and Quality Control.

How NTC Thermistor beta value is calculated?

How to Select NTC Thermistor for Inrush Current Limiting?

NTC Thermistor for temperature measurement and control selecting reference information.

Charging Control with AMWEI NTC Thermistor

Reliable limiting of current surges by AMWEI NTC and PTC thermistor

How to Select NTC Thermistor for Inrush Current Limiting?